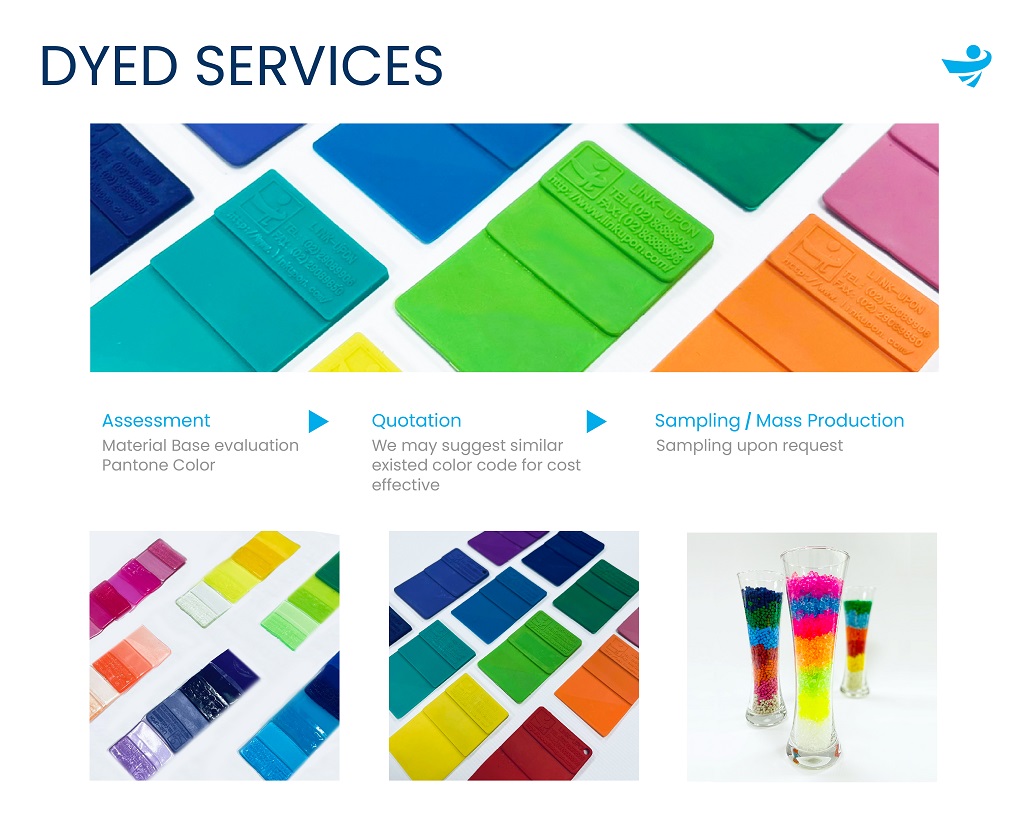

Dyeing Service

We have extensive expertise in color matching for thermoplastic elastomers, drawing materials, and engineering plastics. Based on color targets or physical samples provided by customers, we conduct customized color evaluation and communication. Taking into account the material-specific requirements such as heat resistance and thermal stability, we select suitable base pigments and make step-by-step adjustments to achieve the desired color match.

Why Do Industrial Parts Need Coloring?

In the world of industrial manufacturing, you may have noticed that many components—whether plastic, metal, or rubber—come in different colors. But have you ever wondered why coloring is necessary for industrial parts? In this article, we’ll explore the key reasons behind this seemingly simple yet essential practice.

1. Identification and Classification

One of the most common reasons for coloring industrial parts is easy identification and classification. Different colors can represent various specifications, materials, sizes, or functions, allowing workers to quickly distinguish parts during production, assembly, or maintenance.

Color-coding also helps prevent errors by reducing the risk of mixing up components, which is crucial for maintaining quality and efficiency.

Examples:

• O-rings

• Gaskets

• Connectors

• Cable terminals

These components are often color-coded based on material type or size.

2. Aesthetic Appeal and Brand Identity

Color also plays a significant role in the visual appeal and brand identity of industrial products. A consistent color scheme can enhance the overall appearance of a product and align with the design aesthetic or customer preferences.

Some companies use signature colors as part of their brand recognition, helping their products stand out in the market.

Examples:

• Tools

• Sporting goods

• Electronic device casings

These often come in brand-specific or customized colors.

3. Functional Requirements

Beyond aesthetics, coloring can fulfill specific functional needs in industrial applications:

• UV Resistance: Certain dyes improve UV resistance, extending product lifespan.

• Anti-Static or Conductivity: Some colorants or masterbatches can provide anti-static or conductive properties.

• Specialized Performance: Colors can also serve in infrared shielding, reflectivity, or corrosion resistance.

Examples:

• Industrial plastic housings

• Electronic protection components

4. Traceability and Batch Management

Coloring is a simple yet effective way to ensure traceability in production. Different production batches or manufacturing years can be assigned different colors, making it easier to track products, manage recalls, or perform maintenance.

Examples:

• Aerospace components

• Automotive parts

These industries often use color to support strict quality control and traceability.

5. Compliance and Safety Markings

In many industries, colors are used for safety markings or to meet regulatory standards. Specific colors can indicate hazardous areas, important components, or critical safety features, helping to minimize risks and improve workplace safety.

Examples:

• Pressure pipelines

• Medical devices

• Safety equipment

Final Thoughts:

Coloring industrial parts is about more than just looks—it's about efficiency, safety, performance, and identity. Whether for quick identification, enhanced functionality, or brand differentiation, the right use of color adds real value to industrial products.

Next time you see a brightly colored industrial part, you’ll know—it’s not just for show!